Anyang GEMCO Energy Machinery Co., Ltd (GEMCO) is a manufacturing enterprise specializing in the production of wood pellet machines (such as ring die pellet machines, flat die pellet machines etc), providing you with complete turn-key project services including consultancy, design, manufacture, installation,spare parts, maintenance, etc. GEMCO is the leader in the wood pellet line market in China, where we have successfully carried out hundreds of wood pellet line projects. On-site visits are possible when required.

The general flow chart when you access in the wood pellet machine.

1.Crushing system

If the raw materials is log, wood chip or other big size materials. Generally, you should crush them at first. Because of the best size of raw materials in pelletizing is 3-6mm.

2.Drying system

Drying system is a key equipment in making pellet. In other words, the moisture of the crushed materials is very important in processing.

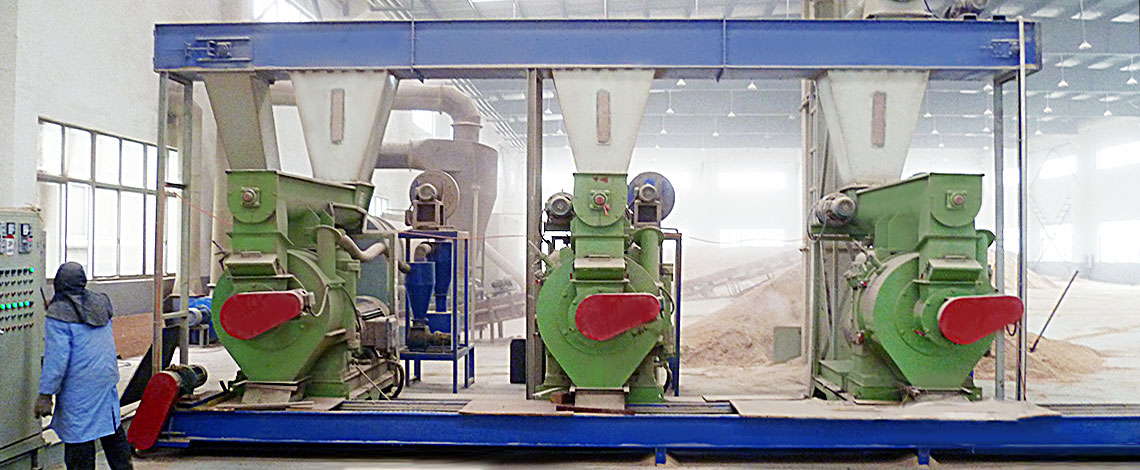

3.Pellet press system

Our wood pellet machine is designed specially for pelletizing all kinds of the wood, such as hardwood and softwood, and we apply different ring die with different compression ratio, whose working principle is extruding between ring die and roller.

4.Cooling and sifting system

Help the pellet low down the temperature and to be sure to get high destiny pellet. Sifting system is for cleaning the powder in pelletizing to get the cleaning pellet for packing.

5.Packing system

Generally, the client asked bulk bag and small bag. Bulk bag is 1Ton/Bag. The small bag is about 15-30kg/Bag.

You can choose both or based on your situation to select the right one.

We own a large scale ring die workshop for the production of molds as well as the most advanced ring die vacuum quenching furnace equipments. Our team can provide you with a customized production line design according to your requirements, raw materials, and the locations of your factory. We will offer you an all-round service including on-site investigation, adjustment and installation, pelletizing training, machine maintenance, and the sales and recycling of the biomass energy pellets. Let us become your reliable source for biomass pelletizing services!