How to Make Agro Waste into Fuel Pellets?

The benefits of pellet fuel• Cost-effective. The raw material is easy to get and it’s very cheap or free except little hauling expense.

• Moisture content of pellets is substantially lower (4% to 8% water, compared to 20% to 60% for agro waste), increasing burn efficiency and allowing for more fuel to be transported in a given truck space, and more energy stored at your site.

• The density of pellet fuel is substantially higher than the agro waste (40 lbs. per cubic foot vs 23 lbs. For straw material).

• Uniform shape and size allows for a smaller and simpler conveying system that reduces costs and pellets pose none of the risk of explosion that fossil fuels do.

• Once the ash is emptied periodically, it can actually double as a fertilizer, and pellet storage poses no soil or water contamination risks.

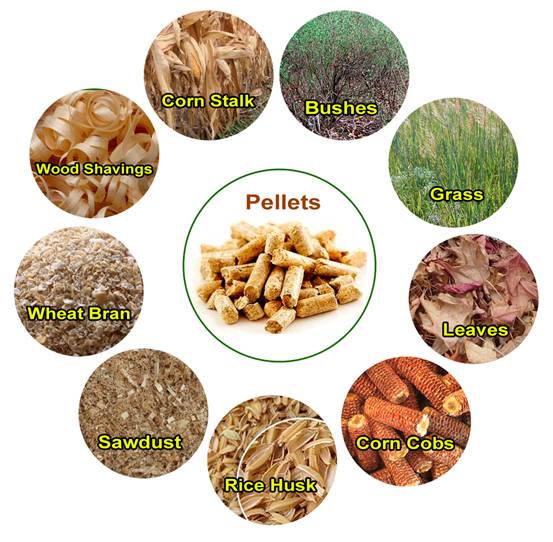

The newly-born biomass pellet technology is a good alternative for the limited fossil fuels. Taking this promising technology into actual production requires several steps. Above all this process, the raw material is the principal problem to solve. Forest is a premium choice for processing biofuel pellets. Straw material such as wheat straw, rice husk, corn straw, sorghum, peanut straw, soybean straw , alfalfa straw and cotton stalk have long been treated as a waste, with the feature of easy to get and cost-effectiveness if be used to process the biofuel pellets will have great potential. It can not only reduce our dependence on fossil fuels, but also increase the farmer’s income at the same time.

Agro Waste Wood Pellets Manufacturing Process

1. Gather the raw material to be used and reduce the size. Chip or shred the raw material until the pieces are no larger than 1 inch (2.5 cm). Use a hammer mill to reduce the size of the raw stock even further. Get the pieces as small as possible without turning it into dust.

2. Dry the material using heat. Content moisture should be 10 to 20 percent for making biomass pellets. Leave the agro waste in the sun to dry naturally, or place the agro waste in wood dryer until it is dried to the desired moisture level.

3. Feed the material through a batch mixer. Pouring it into the mixer will ensure all of the wood pieces become uniform and consistent in density, moisture and size. Make sure there is a rolling drum or an agitator working with the batch mixer.

4. Produce the pellets using a wood pellet mill or, for smaller batches, a pellet press that includes a die and roller. The die is a metal piece with holes drilled through it. The roller goes across the die and presses the wood through the holes into pieces the size of finished pellets. Pellet presses are flat die or ring die. Either type can be used to make wood pellets that are consistent in density and moisture level.

5. Sieve the pellets that did not form properly. Some pieces will fall apart or break during the pressing process. Separate the improperly formed pieces by shaking or sifting them through a pellet sieve.

6. Cool the pellets thoroughly. When the pellets come out of the pellet press, they will be hot and moist. Spread them out and allow them to cool and dry naturally. For industrial production, you can choose a wood pellet dryer.

7. Bag and store the pellets. Put the pellets in plastic bags that are not too big that they cannot be transported, and seal the bags. The pellets will need to be stored in a dry place where they will not become moist.

ExportBureau profile