Ring die pellet machine

What is ring die pellet machine?

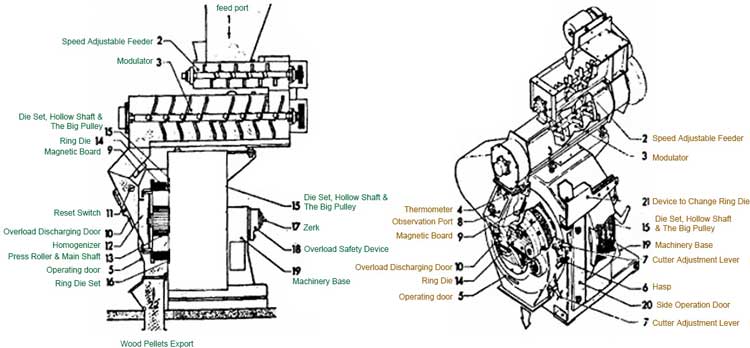

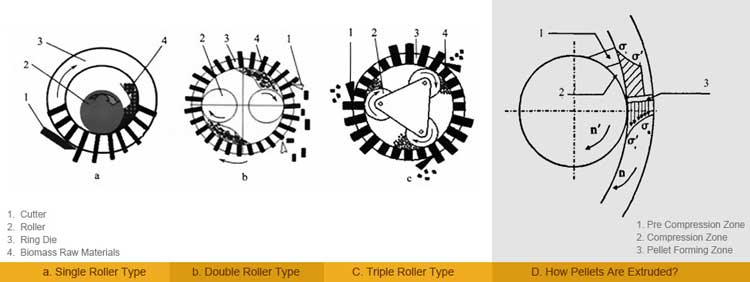

Ring die pellet machine is the core and indispensable part in a complete pellet making line. It is a kind of large scale wood pellet machine. The capacity of ring die pellet machines can range from 500 to 2000kg/h. The reason why it is call ring die pellet machine is that the main part of it is a circular ring, which is called as die, and inside the ring there are two rollers to rotate and extrude the raw materials into the middle to go through the die holes and finally cylindrical pellets are made.

We highly suggest you ring die pellet machine if you are considering setting up a complete biomass pellet line. A high quality and efficient ring die pellet machine is rather important, GEMCO ring die pellet mill is such a dependable machine, it is made from 4Cr13 high-chromium alloy.

Two kinds of GEMCO ring die pellet machines

GEMCO generally supply two kinds of ring die pellet machines. Small ring die pellet machine and large ring die pellet machine.

Small ring die pellet machine

If you want to built a middle scale pellet plant, small ring die pellet machine can be your better choice with the capacity of 500-800kg/h.

| Model | Capacity (kg/h) | Power (kw) | Dimension (mm) | Weight (kg) |

| BPM350 | 500-800kg/h | 30*2+0.75+0.75kw | 2150*1950*1900mm | 2200kg |

Detail show

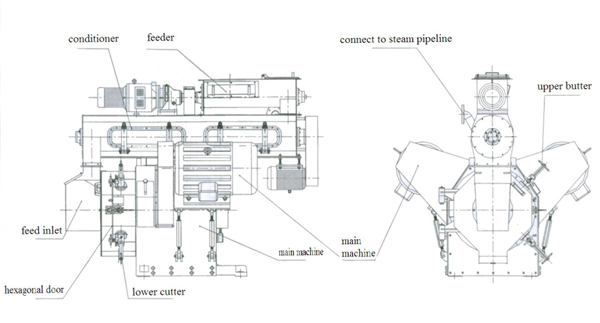

Large ring die pellet machine

This kind of ring die pellet machine is suitable for a wood pellet production line or EFB(palm fiber) pellet making plant. It is also called large wood pellet machines. There are 2 models of large pellet machines, BPM420 that produces 1-1.5ton/h and BPM508 that produces 1.5-2ton/h.

| Model | Capacity (t/h) | Size (W x L x H) | power (kw) |

| BPM420 | 1-1.5 | 1100 x 2600 x 2200 | 90 |

| BPM508 | 1.5-5 | 1200 x 2990 x 2410 | 110 |

Main spare parts

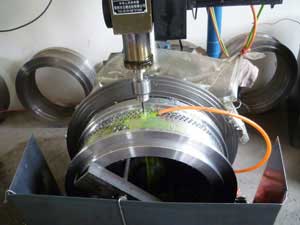

Ring die

Roller shells

Advantages of GEMCO ring die pellet machine

- The pellet size can be 6mm, 8mm, 10mm or 12 mm.

- It has large capacity. We can design 1-3 sets of the wood pellet machines in a complete pellet production line. What’s more, we can parallel several lines together to meet your higher requirement.

- GEMCO ring die pellet machine utilizes imported FAG bearings and oil seal to make sure the machine of higher efficiency, stability and low noise.

- The main working parts adopt strengthened high-chromium alloy and heat treatment, which is extremely well in making hardwood pellets.

- Operator can lubricate the pellet machine even when it is working due to the specially designed lubrication system.

- The latest processing technology of ring die can guarantee it not cracking while in use, which makes sure one ring die can produce at least 800-1000 tons of pellets. (Note: roller and ring die are wearing parts, they shall be changed together even only one of them is worn out.)

- Our ring die pellet machine has cooling system, which ensures continuous working and prevents overheat of the pellet machines if over 8 hours, thus can protect electric motor and other parts, and finally prolong its lifespan.

Raw materials of ring die pellet machine

Ring die pellet machine can process many kinds of raw materials such as household garbage, waste rubber, agricultural wastes and wood residues. Among which agricultural wastes and wood residues are frequently applied in ring die pellet machines.

Agricultural wastes:

wheat straw, rice husk, corncob, corn stalk, tea leaf waste, peanut shell, leaf mustard, sunflower seed shell, jute waste, coffee bean pulp, waste cigarette stem, palm kernel shell, bagasse, bean stalk, coconut shells, dry grass, etc.

Wood residues:

wood shavings, sawdust, and little bark left behind in sawmill, furniture factory, paper plant and construction industry; branches and rotten wood lying by roadside; dead trees killed by insects or diseases.

Compare of ring die pellet mill and flat die pellet mill

Ring die pellet mill is a large pellet mill. So it is mostly used in industrial pellet production and large scale, while flat die pellet mill is usually used in small scale or homemade.

The ring die pellet mill is especially suitable for processing wood and palm fiber. But both ring die and flat die pellet machine can process all kinds of raw materials.

A set of ring die pellet mill has relatively longer service life compared to flat die pellet mill. But the price of flat die pellet mill is relatively lower than ring die pellet machine.

In brief, if you want to produce pellets in large scale, ring die pellet mill is your best choice. In contrast, if you want to make pellets of small scale or just home use, flat die pellet mill is suitable for you!

Wood pellet making machine

This is the key equipment in the pelletizing system. If you want to make the better quality pellet, moisture of the sawdust is a factor, the right compression ratio is also a important factor. Compression ratio lab has set up in our factory and we can make the different testing such us wood, biomass, biofuel,when you sent us the samples, and offer you the ring die with the right compression ratio.This wood pellet making machine adopts double belt-driven system. The motor is compatible with 3phases, 380volts and 50 Hz electricity. The service-life of die and roller is about 800-1000 tons for stainless steel. After the production, you should change 1 set of die and 4 units of roller sheet.

The cooling system for wood pellet making machine is our new design to satisfy with the continuous work more than 8 hours. The main function is to cool down the inside temperature of pressing chamber and guarantee the continuous work. In addition, protect the motor and electrical parts for continuous work.

| Model | GEMCOM350 |

| Feeder motor power | 0.75KW |

| Conditioner motor power | 3KW |

| Main motor power | 30KW×2 |

| Output (t/h) | 3.5-5 |

| Rotation speed of hollow shaft | 335RPM |

| Ring die spec.(mm) |

Inner ring die diameter=Φ350 mm Width of the Working Surface = 100 mm |

| Dimension (mm) | L×W×H=2122×1649×1718 |

| Total weight(kg) | About 2220 |

Advantages of wood pellet making machine:

- Common pellet sizes of 6mm, 8mm, 10mm and 12 mm are available to meet your different requirements.

- High-precision gear transmission is used for the main driver, increasing 20% transmission efficiency compared to belt transmission! Read more about gear transmission vs belt transmission.

- German FAG imported bearings and oil seal give the biomass pellet making machine a higher efficiency, stability and lower noise.

- International standard serpentine spring coupler inside, compact, safe and less machinery failure.

- Strengthened high-chromium alloy and heat treatment is used for main working parts to meet the requirements for pressing hard material, such as hard wood species.

- 10 patented innovation technologies are applied to the biofuel pellet making machine, solving the problem of die cracks, low output and short service time, which frequently occur in the pelletizing industry.

- The special lubrication system allows you to lubricate the machine while it is still working.

- It is also equipped with an air cooling system.

- Stable output and low energy consumption.