Large capacity pellet plant(1-6 T/H)

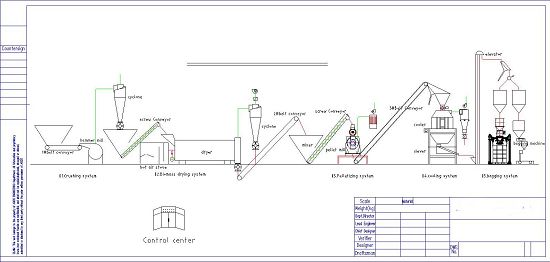

The general flow chart when you access in the wood pellet production line.

1.Crushing system

If the raw materials is log, wood chip or other big size materials. Generally, you should crush them at first. Because of the best size of raw materials in pelletizing is 3-6mm. So, based on different materials, wood chipper and hammer mill is necessary.

2.Drying system

Drying system is a key equipment in making pellet. In other words, the moisture of the crushed materials is very important in processing. If the moisture is high, the pellet will be split at the head. IF the moisture is low, the pellet is difficult to forming. So, the best moisture for pelletizing is 12-16% based on the features of raw materials.

In drying system, Drum drier is the best choice. It consists of drum and hot blast stove. The amount of hot air will be controlled by automatically electrical cabinet and the working speed. This speed can be adjustable.

But the price is also very high cause of the big drum and structure. If the investment has a limit, you also can choose air flow drier. This one was always to be selected by clients.

3.Pellet press system

This is also a key equipment in making pellet. Our wood pellet mill is designed specially for pelletizing all kinds of the wood, such as hardwood and softwood, and we apply different ring die with different compression ratio, whose working principle is extruding between ring die and roller. the high quality of the pellet is the only way to check the pellet press is good or not.

Choose us means you found a good performance machine that it can offer you the good quality pellet and help you to be a leader of the pellet distributors.

4.Cooling and sifting system

Help the pellet low down the temperature and to be sure to get high destiny pellet. Sifting system is for cleaning the powder in pelletizing to get the cleaning pellet for packing.

5.Packing system

After cooling and sifting, packing is the last one job to do. In this part, generally, the client asked bulk bag and small bag. Bulk bag is 1Ton/Bag. The small bag is about 15-30kg/Bag.

You can choose both or based on your situation to select the right one.

6.Electrical cabinet system

Pictures display

Raw materials storage area

Crushing system

Drying system

Cooling and sifting system

Pellet press machine

Bulk and small bag packing machine

Bulk bag

Small bag pellets

Pellets in small bag

wood pellet production line1-2T/H or 2-4T/H

Drying system

Pelletizing system

Electrical cabinet system

wood pellet production line 5-6T/H

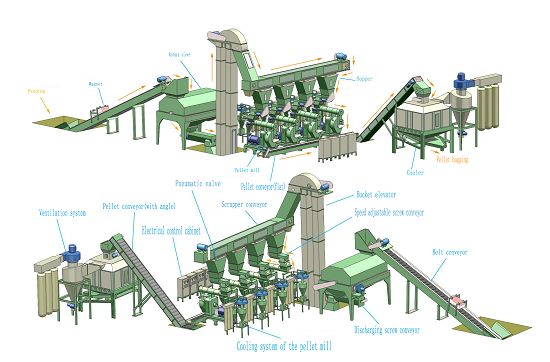

This is 3D drawing to make customer clearly to know how to make the pellet from A to Z.

Take of the impurities from the sawdust by Rotary Sifter and Make drying by Rotary drier

Delivery the sawdust into the pellet press

Pellet press for making pellet

Jumbo Bag