How to build complete wood pellet line?

There are two kinds of complete wood pellet line according to the production capacity. One is small mobile pellet plant, which is one-stop equipment to produce finally pellets, all the necessary equipments are in one pedestal, very flexible and easy to operate. The other one is larger complete wood pellet line, this is a little complex. There are some procedures we should follow, here let’s know about how to build complete wood pellet line.Necessary process of complete wood pellet line

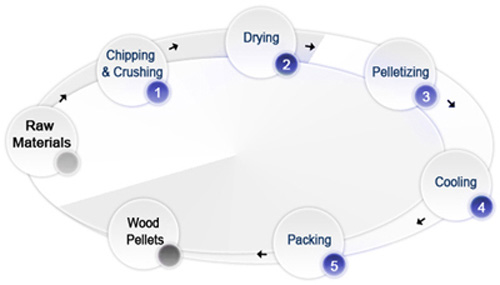

Want to build complete wood pellet line, first and important issue is that you should know the processing flowchart of it. Then on the basis of processing flowchart of complete wood pellet line, you can involve in your business.

Generally speaking, there are such processing procedures of a complete wood pellet line, like: 1. prepare raw materials. 2. Crushing raw materials, if raw materials are logs or other ones more than 5mm in diameter. 3. Drying, if the moisture content of raw materials is higher than 18%. 4. Wood pellets pelletizing, the most important and crucial procedure. 5. Cooling pellets. 6. Wood pellets packing.

Now that you know the processing flowchart, when you want to build a complete wood pellet line, you should consider all the aspects, to think over choosing the most suitable equipments and the proper place to begin your business, you should have a clear knowledge about the floor space, the budget, the driven power and so on.

About the main process of complete wood pellet line, you can refer to our large capacity wood pellet production line. Here I just want to tell you that if you have the idea to build your complete wood pellet line, just follow our processing flowchart, prepare for everything, and we can give you free guidance. We have rich experience in designing and building complete wood pellet lines, can offer all relevant equipments. Our professional export will offer evaluation, customization, and installation and debugging services, our final goal is to meet the requirements of our customers and make sure the best result.

Issues should be considered before building complete wood pellet line

- First, you must guarantee the moisture content of the raw materials. This is quite crucial in the complete wood pellet line. If the moisture content is too high, there will be block problem and may rust the iron parts of the machine. While if lower moisture content, it’s difficult to pelletized and shaped. So the most proper moisture content of the raw materials is 8%-18%. To guarantee this content, dryer is necessary.

- Second, above I mentioned the most important equipment is the pellet machine. So when begin your complete wood pellet line, you must choose the most suitable pellet machine with high quality and reasonable price. As regards the other equipments, almost all the manufacturers who produce pellet machine can offer.

- Third, according to your own situation, actually, not all the equipments are essential for a complete wood pellet plant, you should choose the real need one depend on your plan, your production capacity, your budget and so on.

- Fourth, you must consider the place where you want to build your complete wood pellet line, the transportation, the electric power, the acreage and etc. Reasonable programming all the things in advance is necessary.