How to Select Your Pellet Mill?

Two types of the pellet mill

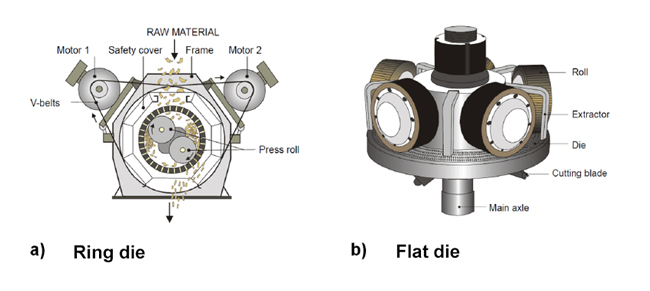

According to the production capacity and working principle of different pellet mills, there are mainly two types of pellet mills, namely, flat die pellet mill and ring die pellet mill.

Flat die pellet mill

Feature

Flat die pellet mill is rather simple in structure, there are many different drive engines of flat die pellet mill. Such as flat die pellet mill with electric motor, diesel engine, gasoline and PTO. Flat die pellet mill has the wide processing range, can process many kinds of raw materials like the hardwood, pinewood, peanut shell, and all the biomass raw material what we can find into the pellet without any additive. Because of the automatic regulating function of the pressing wheel, the material will be not crowded, that can ensure the stability of molding.

Working principle

On the surface of flat die there are many holes, when the raw material fall on the surface, the roller and die will be extruded each other, and the material will be pressed into the die holes and be compressed into the cylindrical object and come out from the bottom of the holes. After that, the cutter will cut the cylindrical object into the pellet.

Ring die pellet mill

Feature

Ring die pellet mill is suitable for the large scale production of wood pellets, it has high efficient and low consumption. In the large wood pellet plant, usually ring die pellet mill is extremely important, it makes pellets together with other equipments.

Working principle

Generally speaking, there are two to four roller and driven roller in a ring die pellet mill, and the ring die is a cylinder with many holes. The rollers in the cylinder will press the material into the holes after the material be put into the ring die pellet mill workplace, and then, the material will be squeezed out from the cylinder, and the cutter will cut them into the cylindrical pellets.

How to select your pellet mill

Type. Now that there are flat die pellet mill and ring die pellet mill, one of the important factors to choose suitable pellet mill is according to your real requirements. That is because the ring die pellet mill can have higher efficiency with higher cost, but flat die pellet mill with lower cost to produce pellets, so comparatively speaking, the ring die pellet mill is fit for the large and middle plant, and the flat die pellet mill is fit for the small scale producing.

Appearance quality. This is another factor you should consider, The spray lacquer of the pellet mill should balance and fastness, and there is no leakage of paint. The part which used the stainless steel should has the smooth surface, and no knock against scratches.

The spare parts should be paid attention are different. Flat die pellet mill should mainly check the cutter’s quality, and the ring die pellet mill should check the roller bracket and the roller’s fastening situation.

Security checks. This refers to the ring die pellet mill. There is a security linkage device on the main shaft in order to avoid the sundries go into the ring die pellet mill to damage the machine. If the sundries enter the ring die, the resistance of main shaft will increase rapidly, and the safety cock will break off. Then, the convex side of the clutch will touch a shafting fork of the limit switch, and shut off the power supply of the main shaft motor, ensure the pellet mill can’t be damaged. So, when select the ring die pellet mill, you should check that if the clutch convex side can touch the shafting fork of the limit switch or not. If can’t touch then don’t buy it.